The Festool Domino joiner has revolutionized joinery, offering a level of precision and efficiency that stands out in the realm of woodworking tools. Unlike traditional methods, the Domino system uses a unique, patented cutting action to create mortises that perfectly match the proprietary tenons, delivering strong and accurate joints with ease. Woodworkers find Festool’s system simplifies tasks like aligning boards and securing joints, reducing the time and effort required to achieve professional results.

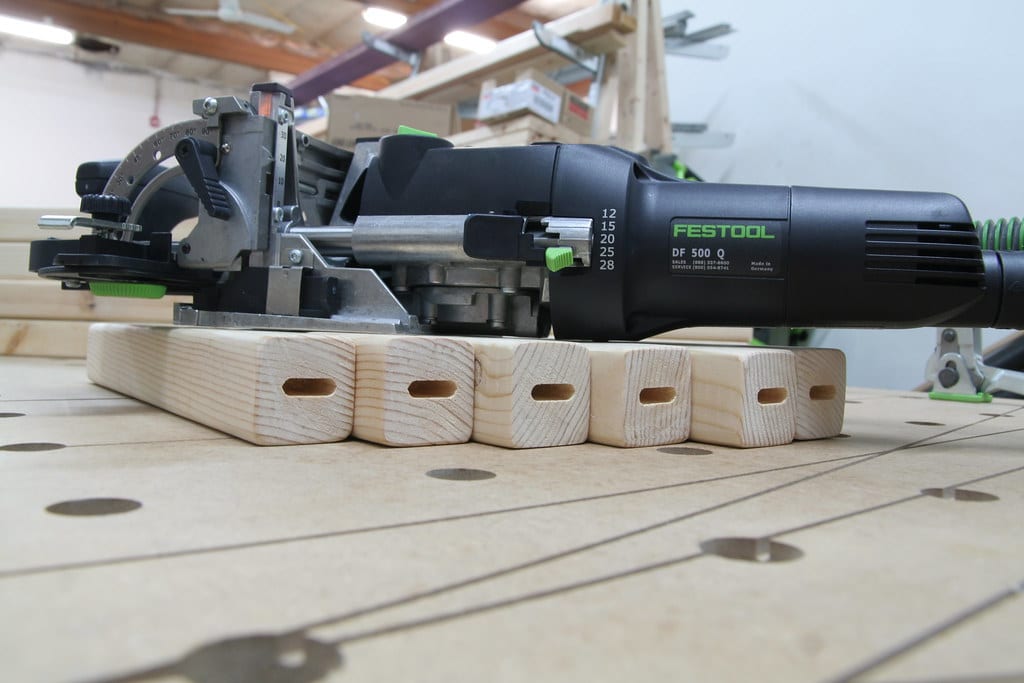

Expanding upon the capabilities of the basic biscuit joiner, the Festool Domino lineup includes robust tools like the DOMINO DF 500 and the DOMINO XL DF 700, catering to a range of project sizes from delicate furniture assemblies to large-scale construction. The machines feature ergonomic designs, adjustable fences, and clear depth settings to accommodate various materials and joint types. What sets Festool apart is not only these tools’ precise engineering but also the comprehensive set of accessories designed to maximize the potential of the Domino system.

Key Takeaways

- The Festool Domino joiner offers precision joinery with its patented cutting action and matching tenons.

- Festool’s range includes versatile tools like the DF 500 and DF 700, accommodating different project requirements.

- Festool provides a suite of ergonomic and precision-focused accessories for the Domino system.

Understanding the Festool Domino System

The Festool Domino System revolutionizes joinery tasks, combining speed and precision. Uniquely designed for the creation of a mortise and tenon joinery, this system elevates traditional approaches and ensures stronger joints with less effort.

Principles of Joining

The Domino joining system utilizes a patented routing principle where a round, oblong hole (mortise) is created to fit the specially designed rectangular tenons, or dominoes. Unlike traditional square mortises that are time-consuming and require exacting alignment, the domino effectuates a more flexible and unique positioning that can adjust properly in the wood. This allows for easy alignment and a solid, durable fit.

Domino System Components

At the heart of this system is the Domino joiner, specifically models like the DF 500 and DF 700. These tools are accompanied by a range of accessories from Domino slot cutters of various diameters to carbide tip spiral bits and a selection of Domino tenons and wooden dowels. All components are efficiently stored in the Systainer SYS3 M 187, ensuring portability and organization.

Technical Data Specifications

Technical Data for DF 500:

- Idle Engine Speed: Up to 25,500 rpm

- Max. Routing Depth: 28 mm

- Routing Depth Adjustment: 5-30 mm

- Dust Extraction Connection Dia.: 27 mm

- Routing Height Adjustment: 5-30 mm

- Cable Length: 2.5 m

- Power Consumption: 420 W

Technical Data for DF 700:

- Idle Engine Speed: 21,000 rpm

- Max. Routing Depth: 70 mm

- Routing Depth Adjustment: 10-50 mm

- Dust Extraction Connection Dia.: 27 mm

- Routing Height Adjustment: 10-50 mm

- Cable Length: 5 m

- Power Consumption: 720 W

Your Domino joiner is engineered to work at an optimal idle engine speed, ensuring a clean cut and efficient operations which play a vital role in the overall durability and robustness of the joinery. The dust extraction feature keeps your workspace clean and helps maintain visibility for precise alignment.

Tools and Accessories

When you’re aiming for seamless joinery and woodworking precision, the right tools and accessories are crucial. Festool’s Domino joiners, notably the DF 500 and DF 700, along with their assortments of accessories, ensure you can tackle any project with confidence.

Domino Joiner Models

DF 500 Series:

- DF 500 Q: A robust yet versatile joiner designed for everyday use.

- DF 500 Q-Plus: Includes additional features for enhanced functionality.

- DF 500 Q-Set: This set provides a comprehensive solution, combining the DF 500 Q-Plus joiner with a variety of useful accessories.

DF 700 Series:

- Domino XL Joiner (DF 700): Tailored for larger scale projects demanding wider and deeper dominos.

Each joiner is engineered to work seamlessly with Festool’s system of accessories, offering you tailored solutions for your project needs.

Precision Engineering

Accessories:

- Trim Stop: Enables you to make precise and repeatable cuts on narrow workpieces.

- Cross Stop: For repeated mortises without needing to mark out.

- Support Bracket: Gives additional support for working on edges.

- Pivoting Fence: Allows for creating angled mortises from 0 to 90 degrees.

Precision & Control:

- Mortise Width Adjustment: Customize the fit for tighter or looser tenon joints.

- Depth Control: Multiple depth stop settings for quick and precise adjustment.

- Stepped Height Stop: Facilitates rapid and accurate setting for various material thicknesses.

Performance:

- Rapid Bit Change: For quick and efficient bit changes, reducing downtime.

- Depth Stop for Routing Depth: Ensures consistent mortise depths across your project.

These precision-engineered accessories empower you to execute perfect, precise mortise placement with ease, enhancing your craftsmanship with every piece you create.

Joinery Techniques

In woodworking, precision and strength are critical, and the Festool Domino system elevates both by expertly combining the time-tested mortise and tenon joint with innovative machine precision. Your projects can achieve robust joints suited for a variety of applications utilizing the system’s routing principle and customizable settings.

Mortises and Tenons

Mortises and tenons are fundamental to woodworking joinery, where a protruding tenon fits into a corresponding mortise to form a tight, interlocking connection. The Domino joiner simplifies this process through the routing principle. It cuts mortises with remarkable accuracy, ensuring perfectly matched openings for the tenons. When creating joints with the Domino joiner, you must pay deliberate attention to alignment. Consistently referencing the same face and side ensures that the mortises align perfectly with the tenons, which is critical for the integrity of your assembly.

Adjustments and Settings

The versatility of the Domino joiner arises from its functionality to adjust both the mortise width and the depth.

- For mortise width adjustment, you typically should match the width to the size of the tenon for standard fittings. However, if you require some play for alignment purposes, you can select a wider setting. This slight increase in width facilitates alignment during glue-up, accommodating for any minor discrepancies.

- Depth control is equally as important, and the Domino allows for precise routing depth adjustment. Deeper mortises provide increased strength for structural components, while shallower ones may suffice for non-structural, decorative applications. You can adjust the routing depth according to the needs of your specific project.

By understanding the impact of each setting and the proper use of the Domino joiner, you can execute various joinery techniques with confidence, from straightforward connections to more complex angles and alignments.

Practical Applications

When integrating the Festool Domino joining system into your projects, you’ll recognize the adaptability it provides for various joining tasks and the seamless compatibility with a range of materials and applications.

Workpiece Positioning and Applications

The Festool Domino jointing system offers precision in workpiece positioning. Whether you’re working with narrow or wide pieces, the handrail fence and trim stop ensure accurate alignment. For example, when joining panels for furniture construction, the handrail fence assists in stabilizing vertical joints, while the trim stop is particularly useful for narrow workpieces, such as frames. The integrated scales and easy adjustments on these accessories facilitate quick and repeatable settings for different material thicknesses.

- Joints: Create strong mortise-and-tenon joints efficiently for applications like cabinets, chairs, or tables.

- Cross Stop: The cross stop enables precise repeat holes without having to mark out the joints, enhancing your productivity.

Versatility and Compatibility

The Festool Domino system epitomizes versatility. Its range of Domino tenons, or ‘cookies,’ are available in different sizes to suit material thicknesses and offer flexibility across various application areas. You can effectively join everything from delicate inlay work to robust furniture parts.

- Domino DF 500: This tool is ideal for most joining applications, providing a balanced combination of strength and ease of use.

- Accessories: Expand the Domino’s capabilities with additional accessories like cross stops, widening its functionality.

- Online Services: Leverage online resources for guidance or to purchase replacement parts and accessories.

By understanding the practical uses of these features, you maximize the potential of your Festool Domino system for a broad spectrum of joining tasks.

Usage and Safety Instructions

Before operating your Festool Domino, it’s crucial to understand the manufacturer’s recommended procedures and safety measures. This will help ensure the longevity of your machine and prevent accidents during use.

Operating the Festool Domino

When using the Festool Domino, always adhere to the specific operating guidelines provided by the manufacturer. Start by selecting the appropriate settings for the hole width, domino size, and cutter depth according to the task at hand. Ensuring proper adjustments will lead to precise joinery and improved work quality.

- Safety Checklist

- Ensure work area is well-lit and free from obstructions.

- Verify the power tool is disconnected before making adjustments.

- Always wear protective gear, such as safety glasses and hearing protection.

Domino Machine Maintenance

Regular maintenance of your Festool Domino is essential to keep it in top condition. Clean the machine after each use, removing any dust and debris that could accumulate and lead to malfunctions. Check the Festool service website for detailed maintenance instructions and additional help, including Festool tutorials and warranty information. Register your machine with MyFestool to stay updated on service and support options.

- Maintenance Routine

- Inspect the power cord and plug for damage regularly.

- Replace worn cutters and parts with genuine Festool components.

- Lubricate moving parts as specified in the tool’s user manual.

By following the recommended operating and maintenance instructions, you’ll be able to get the best performance out of your Festool Domino while prioritizing safety and machine longevity. For any questions or additional assistance, reach out to Festool’s online services or consult their extensive Festool media resources.

Festool Brand and Innovation

Festool is a brand that stands for exceptional quality and groundbreaking innovation in the field of professional woodworking tools. Their commitment to excellence is evident through their advanced technologies and responsive customer service.

Company Information

Festool began its journey as Festo Tooltechnic and over the years, it has established itself as an independent brand renowned for its unwavering dedication to quality and innovation in the realm of professional tools. The company history of Festool illustrates its evolution and relocation to Wendlingen, ensuring that it remains at the forefront of tool technology development.

Advanced Tool Technologies

Festool is synonymous with cutting-edge tool technology, particularly evident in their creation of the DOMINO joining system. This high-precision joiner revolutionizes woodworking by significantly improving efficiency and accuracy. Moreover, Festool has embraced cordless solutions, exemplifying their commitment to innovation and the continuous expansion of their professional tool offerings.

Service and Customer Support

Service excellence is a cornerstone of the Festool brand. Festool stands out with its robust services, including a comprehensive warranty, efficient online services, and the MyFestool portal for an enhanced customer experience. Festool also provides Festool media resources to support and educate users, ensuring they get the most out of their tools.

Purchasing and After-Sales

When you invest in Festool products, you benefit from top-notch customer service and comprehensive support options that include warranties, an online portal, and educational resources.

Where to Buy Festool Products

You can purchase Festool tools, including the DOMINO DF 500 Q-Plus joiner, through authorized dealers, directly from Festool online, or through online retailers like Amazon. When buying online, you’ll have access to the full range of Festool products, easy-to-navigate purchasing options, and the opportunity to create an account for a more tailored shopping experience.

Customer Service and Support

Festool takes pride in its after-sales support. Once you’ve made your purchase, you can register your tool on the MyFestool portal. By doing so, you’ll have access to a suite of online services, including warranty registration, detailed tutorials, and personalized assistance.

- Warranty: Festool provides a comprehensive service inclusive of a warranty for your peace of mind. Ensure to check specifics for your region as terms may vary.

- Service: Should your tool need repair, Festool’s service process is streamlined for efficiency. You’re instructed on how to send in your product for maintenance, minimizing downtime.

- Online Tutorials: To help you get the most out of your Festool tools, the company offers a variety of tutorials, ensuring you can master your new equipment with ease.

Remember to keep your tool registered on MyFestool for up-to-date info and to maintain easy access to Festool’s online services.

Efficiency and Workflows

Enhancing your woodworking projects with the Festool Domino involves adopting advanced techniques that boost efficiency and manage your workspace effectively. Embrace methods that streamline tasks, maintain cleanliness, and refine joinery to elevate your craft.

Streamlining Work Processes

Uniformity is Key: Utilize the Festool Domino to create consistent and accurate mortise cuts in your workpieces. By simplifying repetitive tasks, you can swiftly produce multiple joinery elements, ensuring each joint fits precisely without constant readjustments.

- Cut Setting Adjustments: Adjust cut size with predefined settings, enabling rapid switching between different joint sizes for diverse project requirements.

Dust Extraction and Workspace Management

Impeccable Cleaning: The Festool Domino supports efficient dust extraction, directly connecting to your dust extraction system to keep your workspace clean. A clear area not only reduces cleanup time but also extends tool longevity and ensures better joinery results by removing debris that could interfere with the snug fit of tenons.

- Hose Attachment Ease: Simply connect your dust extractor hose to maintain a dust-free environment.

Advanced Joining Techniques

Complex Angles: With the Festool Domino, you can tackle complex joining techniques, including angled joints, with ease. The Domino joiner’s precise alignment features and adjustable fence allow for creating tight-fitting joints at a variety of angles, expanding your design possibilities.

- Versatile Domains: Harness the tool’s capability for varied joint types, including but not limited to:

- Flush joints: for a smooth, seamless finish.

- Beveled joints: for unique geometric shapes.

- Wide joints: ensuring stability in large-scale projects.

By incorporating these principles into your workflow, your use of the Festool Domino joiner becomes not just about joining pieces of wood, but about elevating craftsmanship through efficient practices.

Frequently Asked Questions

When incorporating the Festool Domino into your woodworking, understanding the different models and appropriate applications is crucial for achieving the best results.

What are the main differences between the Festool Domino DF 500 and DF 700 models?

The Festool Domino DF 500 is ideal for making smaller mortises for furniture, while the Domino DF 700, also known as the Domino XL, is better suited for larger, more structural joinery due to its capacity to create wider and deeper mortises.

Can I find a reliable alternative to Festool Domino that is more budget-friendly?

There are alternative joining systems available that can be more cost-effective, but they may not offer the same precision and versatility as the Festool Domino.

Are there any distinct advantages of using the Festool Domino XL for joinery?

Using the Festool Domino XL, you gain the advantage of tackling larger projects such as doors and furniture frames with its extended range of tenon sizes and deeper plunge depth.

What are the considerations when buying a used Festool Domino joiner?

When purchasing a used Festool Domino, check for completeness of the set, the condition of the machine and accessories, any signs of excessive wear, and ensure it functions correctly.

How do I choose the appropriate Domino tenons for my woodworking project?

Select Domino tenons based on the thickness and width of your material; ensure the tenon fits snugly in the mortise and that it’s proportionate to the size and strength required for the joint.

Are there any other manufacturers that produce a joiner similar to the Festool Domino system?

Other manufacturers may offer comparable loose tenon joinery systems, but Festool’s efficiency, precision, and system integration set the Domino apart as a unique tool in the market.